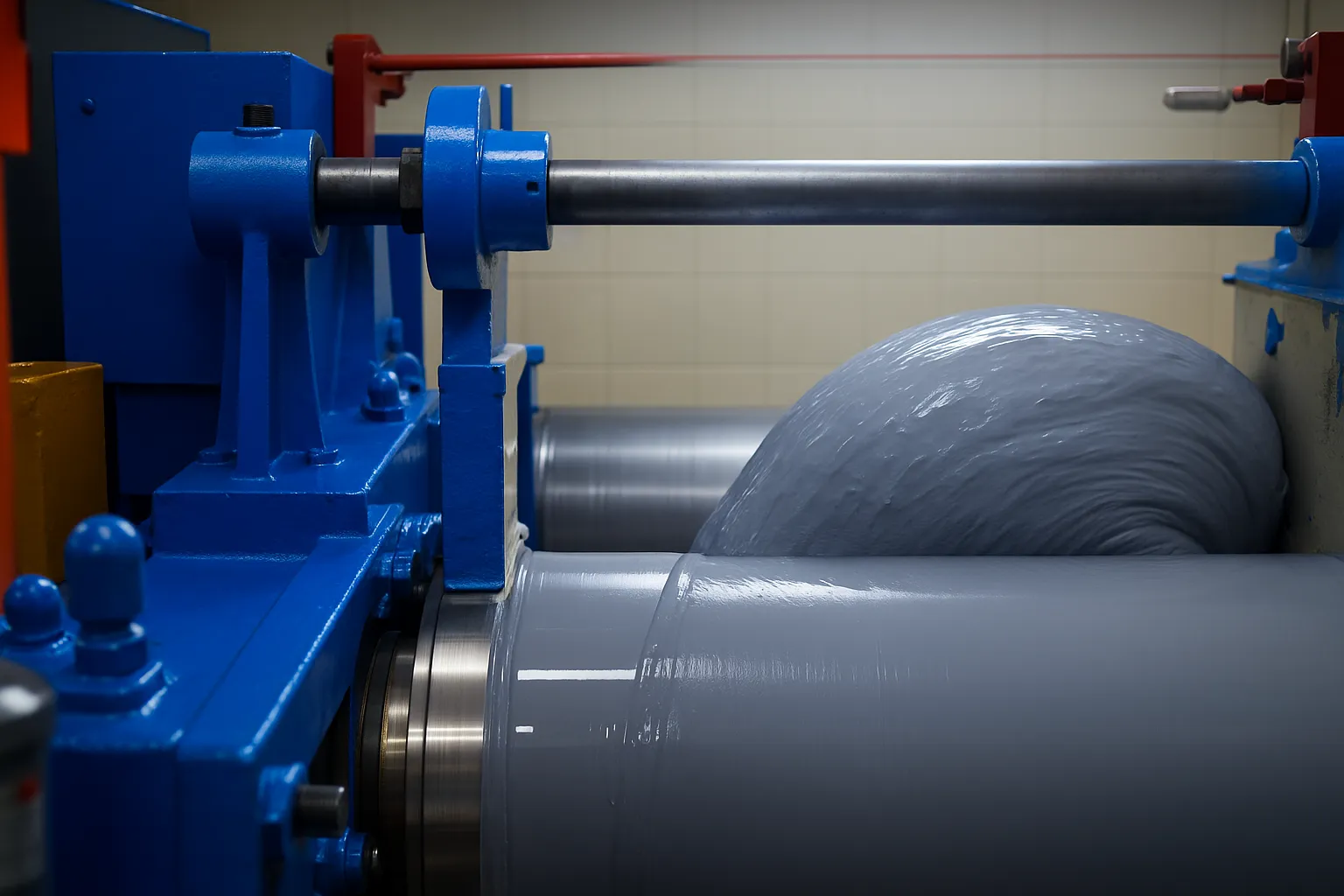

In-House Seal Production

At SealShift, we take immense pride in our comprehensive in-house production capabilities that we've developed and refined over years of industry experience. By maintaining complete control over every aspect of the manufacturing process, we consistently deliver superior quality inflatable seal products that meet our exacting standards.

Our vertically integrated approach allows us to offer impressively short lead times without compromising on quality. From initial design to final testing, our expert team oversees each step, ensuring that every inflatable seal we produce exceeds expectations in performance and reliability.

When you choose SealShift, you're not only selecting a provider of superior products but a partner who understands the value of time in today's competitive business environment. We've streamlined our manufacturing processes to minimize delays while maintaining the highest standards of quality control. See our case studies for examples of our successful implementations.