Super Yacht Hatch Sealing System

A premier yacht builder approached SealShift with a challenging requirement: develop a sophisticated sealing solution for luxury yacht deck hatches that would provide superior weatherproofing while maintaining the elegant aesthetics of their vessels. This project showcases our expertise in marine applications and custom inflatable seal design.

The demanding marine environment, with its constant exposure to saltwater, intense UV radiation, and extreme temperature fluctuations, required an innovative approach to ensure long-term reliability without compromising the yacht's premium design standards.

The Challenge

The SealShift engineering team identified several critical requirements for this premium application:

- Complete weatherproofing: The seal needed to prevent water ingress during heavy weather conditions while maintaining integrity under pressure from deck washing and waves.

- UV and saltwater resistance: Continuous exposure to intense sunlight and corrosive saltwater demanded exceptional material durability.

- Low-profile integration: The solution had to integrate seamlessly with the yacht's sophisticated design without compromising aesthetics.

- Advanced compound formulation: A 2-part compound system featuring a UV-stabilized outer layer with a specially formulated flexible inner core for optimal inflation characteristics.

- Low-profile design: Custom-engineered to integrate with the yacht's existing hatch design while maintaining the elegant aesthetic requirements. The client's existing hatch seals were failing to provide consistent weatherproofing during harsh marine conditions, leading to water ingress and potential damage to valuable interior spaces. Traditional compression seals were also creating excessive closing force requirements and premature wear on expensive hardware. Our marine-grade inflatable seals offered the perfect solution.

- Controlled inflation system: A precision pneumatic control system allowing for perfect seal pressure while permitting easy operation.

- Saltwater protection: Enhanced chemical resistance to withstand constant exposure to salt spray and cleaning agents.

Our Solution

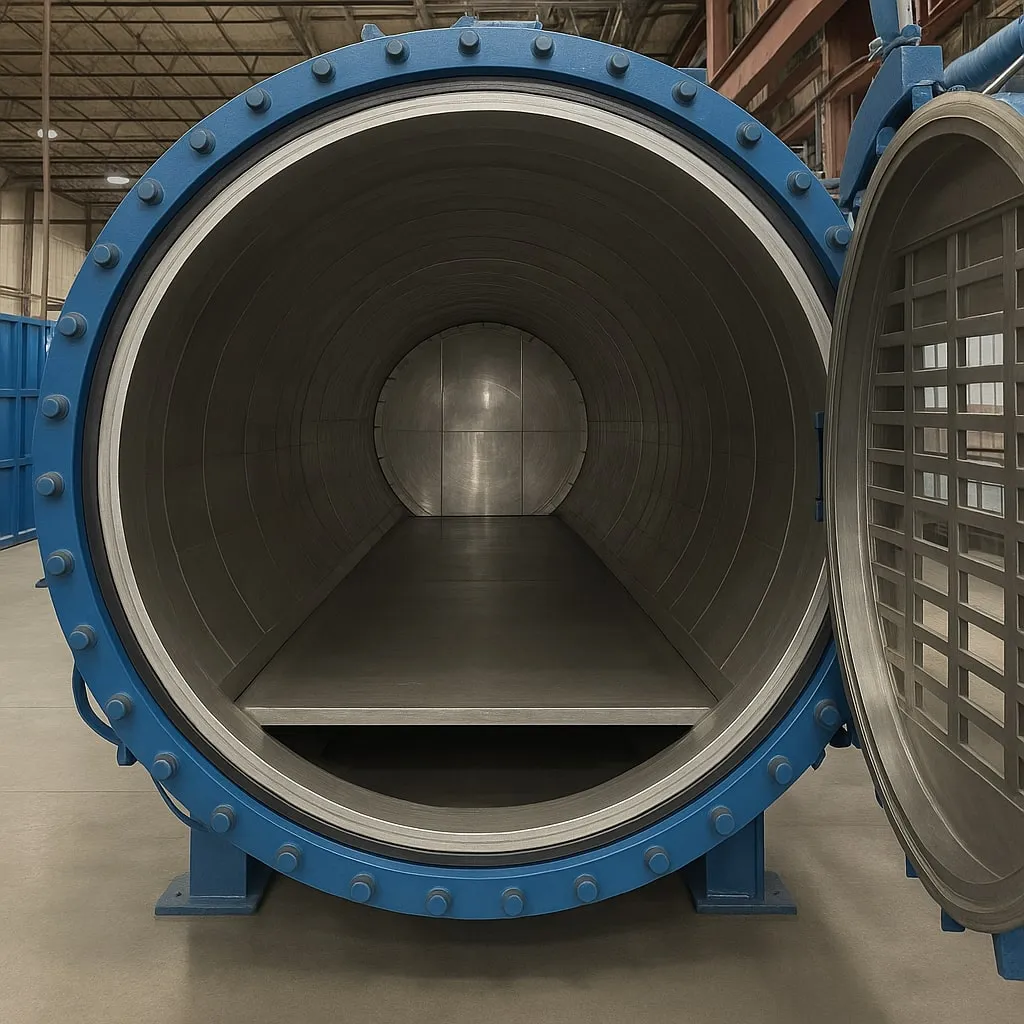

SealShift's engineering team developed a specialized marine-grade inflatable seal system designed specifically for the luxury yacht environment:

Each seal underwent rigorous testing including accelerated UV aging, salt spray exposure, and over 10,000 operational cycles to validate the design before installation across the client's fleet of luxury vessels.

Results & Benefits

100% Weather Protection

Complete elimination of water ingress even in severe marine conditions

87% Reliability Improvement

Dramatic increase in seal performance compared to previous solutions

2-Year Warranty

Comprehensive coverage reflecting confidence in the solution's durability

Long-Term Impact

The super yacht manufacturer has implemented SealShift's solution across their entire new vessel lineup, with retrofitting programs available for existing yachts. The improved reliability has become a selling point in their marketing materials, emphasizing the attention to detail and quality that sets their vessels apart.

The partnership continues with SealShift now developing advanced solutions for other marine applications including dive platforms, tender garages, and submersible deployment systems.