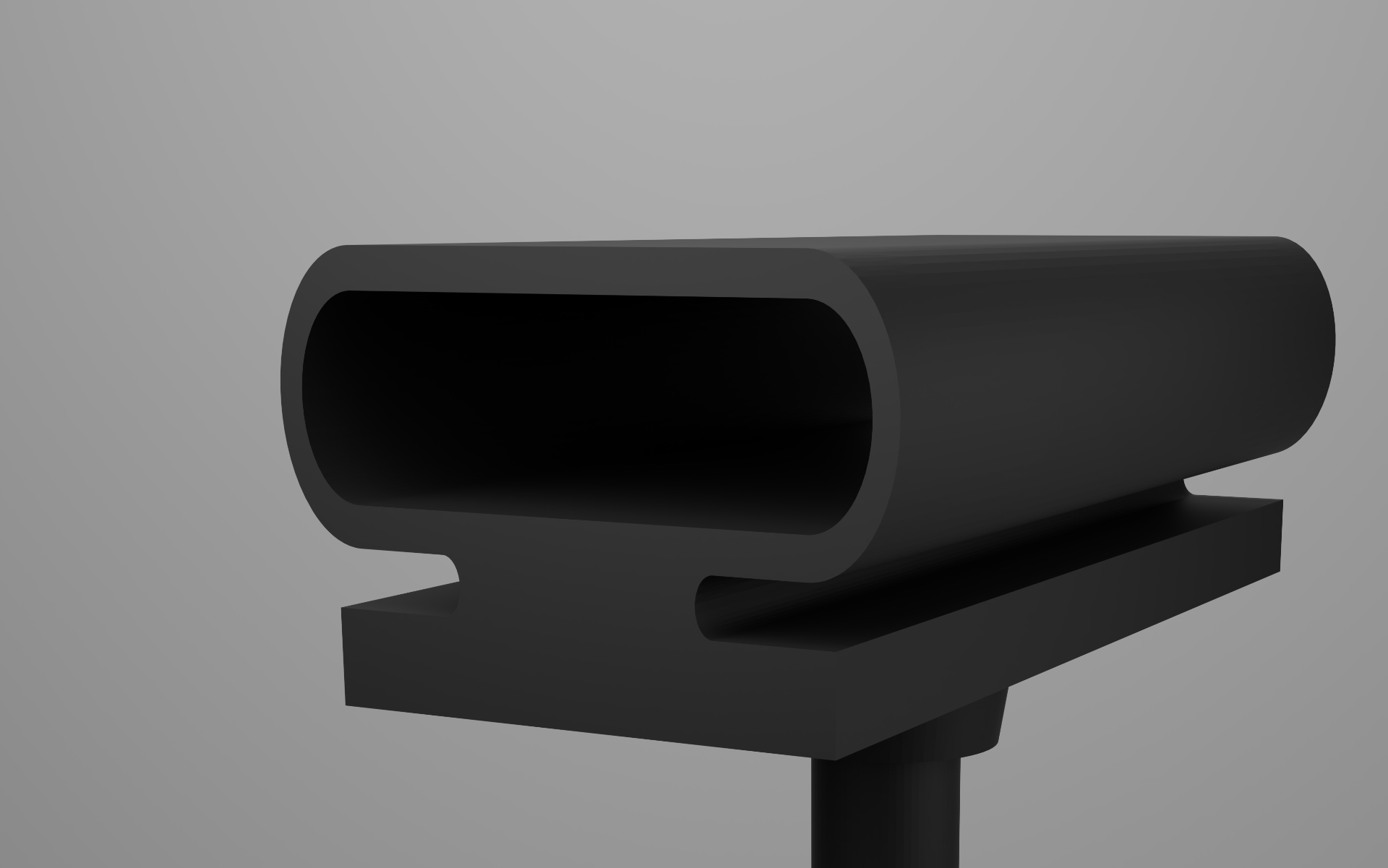

SS-FOOT-FLAT

A versatile retainer profile designed for applications requiring a secure mounting solution with flat-top sealing surface.

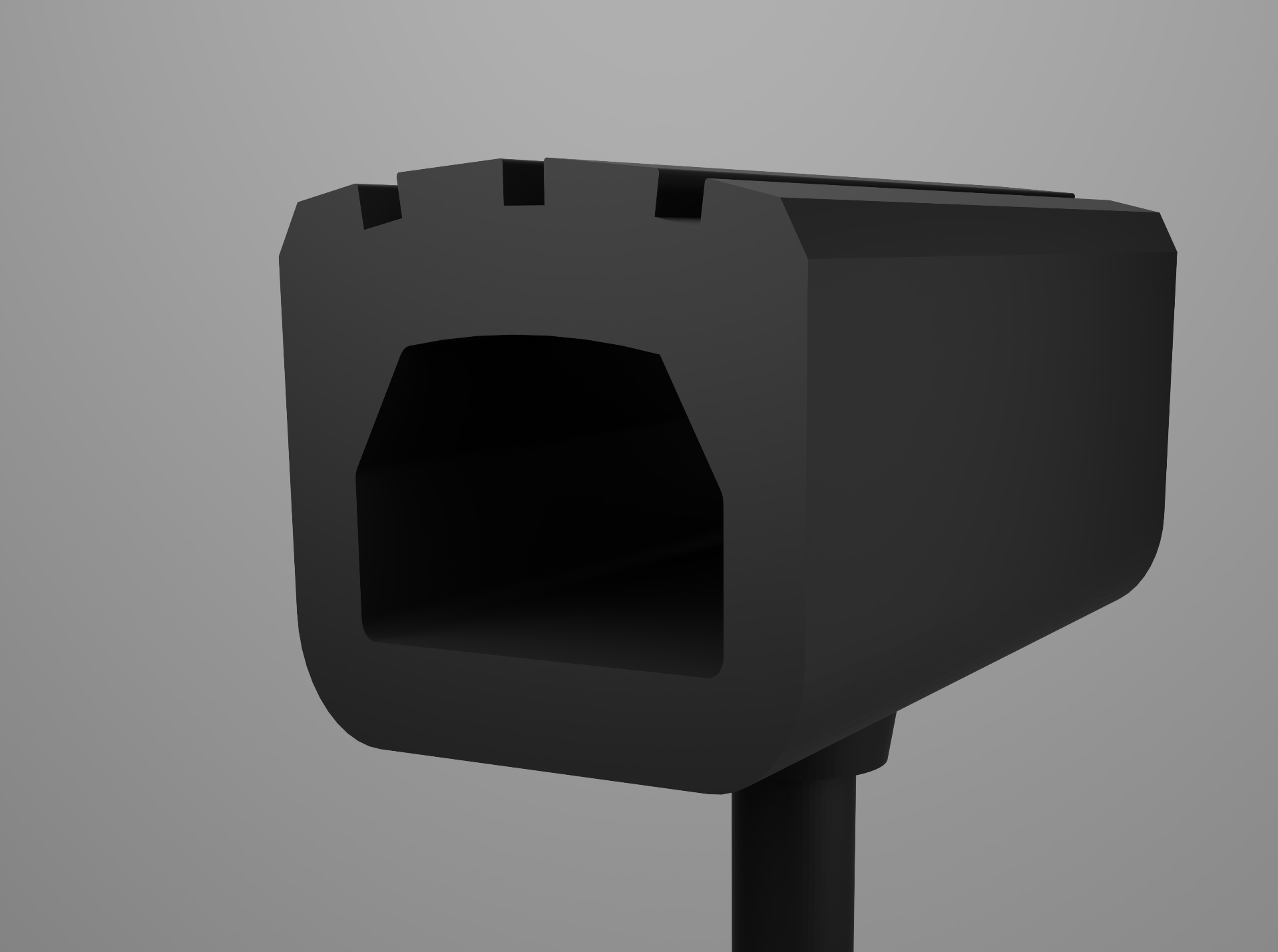

SS-RUGGED-RIDGE

High-pressure profile specifically designed to perform exceptionally well in applications requiring superior sealing against significant pressure differentials.

SS-FLEX-FROGLEG

Specifically designed for applications where a lower profile is required with excellent deflection properties and resilience.

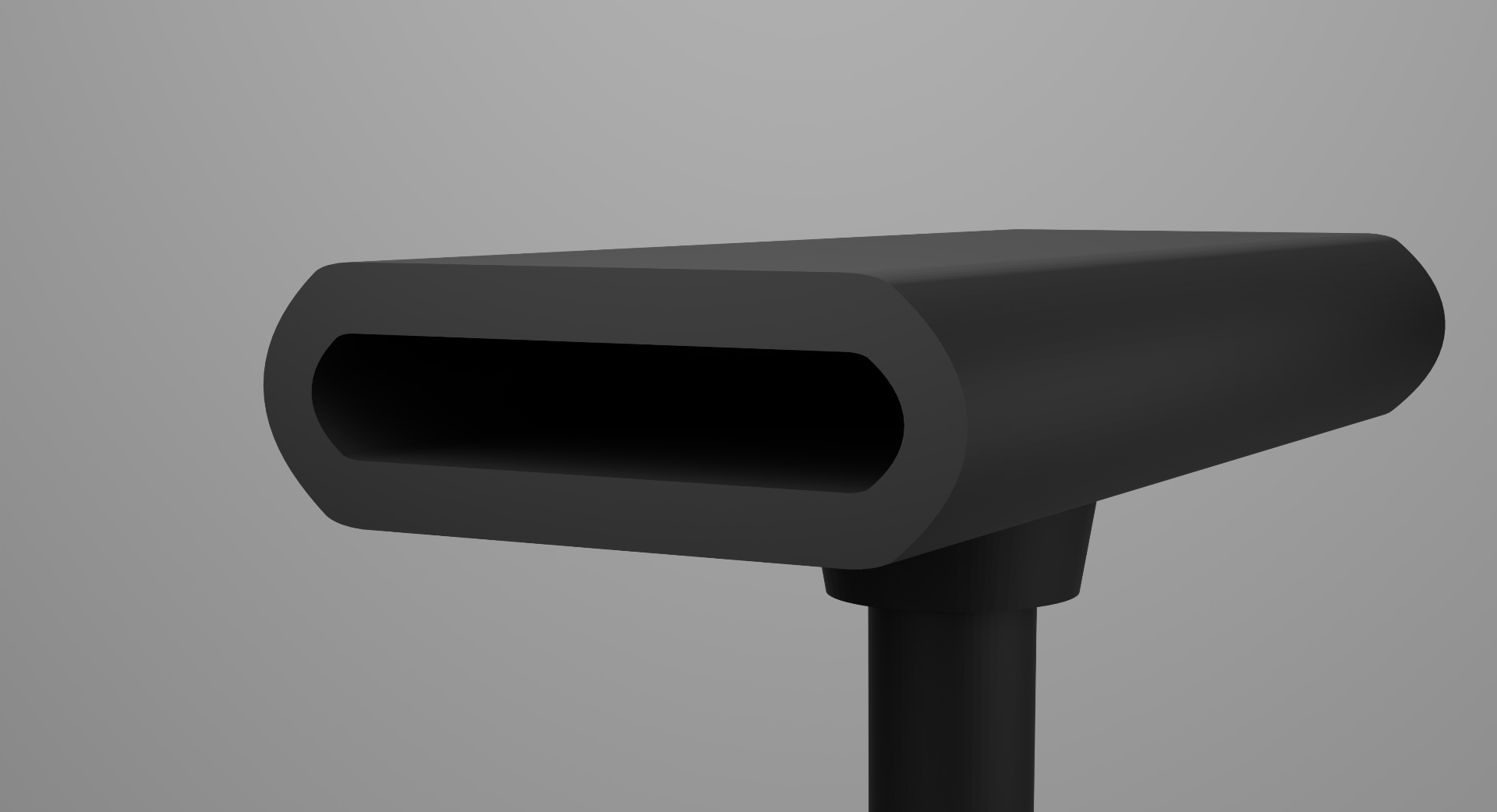

SS-FLEX-FLAT

Designed for applications requiring a compact, reliable seal with excellent conformability to irregular surfaces.

SS-RUGGED-FLAT

Designed for applications requiring a broad sealing area with maximized contact surface for optimal sealing effectiveness.

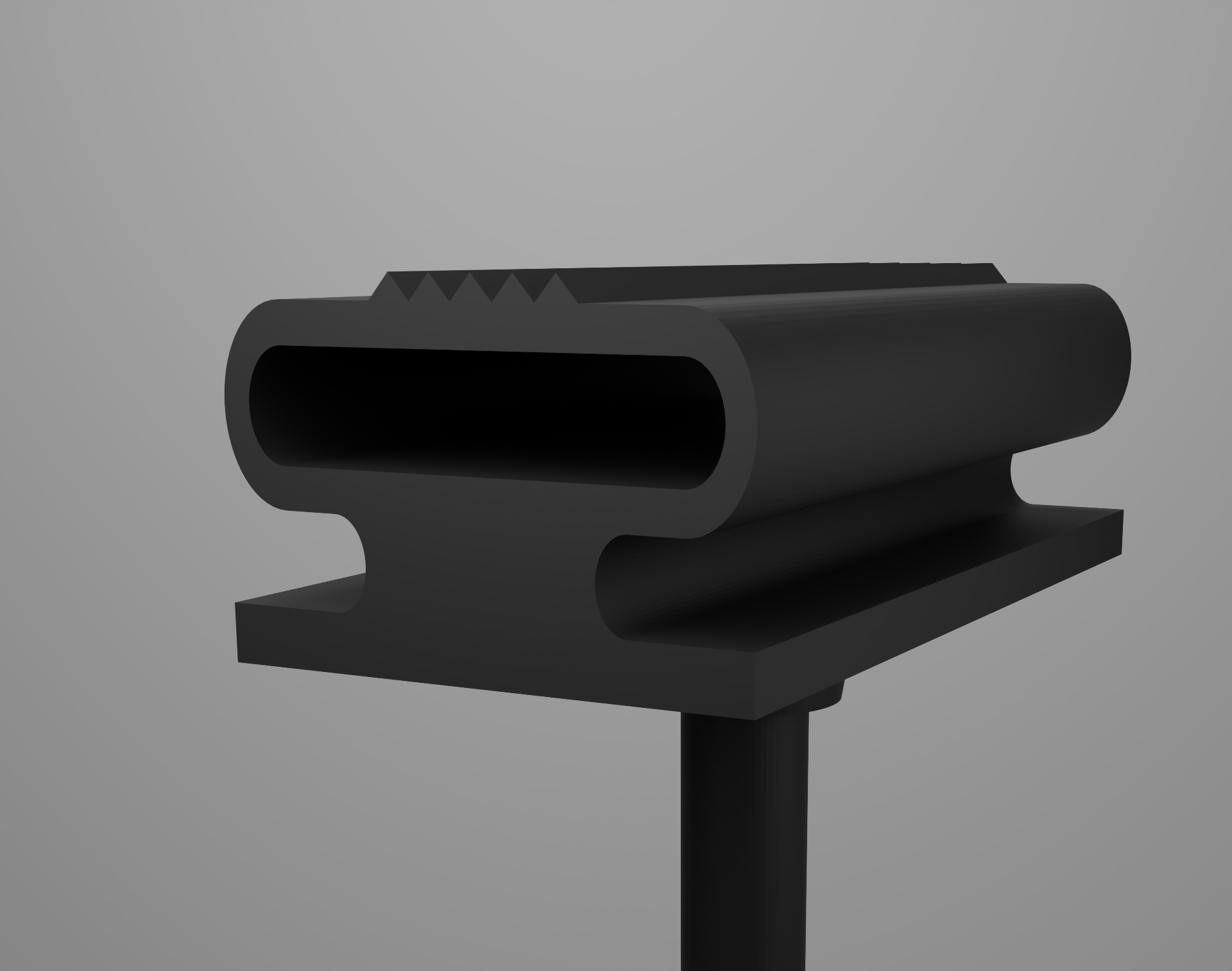

SS-FOOT-RIDGE

Designed for applications requiring secure mounting with a ridged sealing surface for improved contact and pressure distribution.