Engineered for Your Specific Challenges

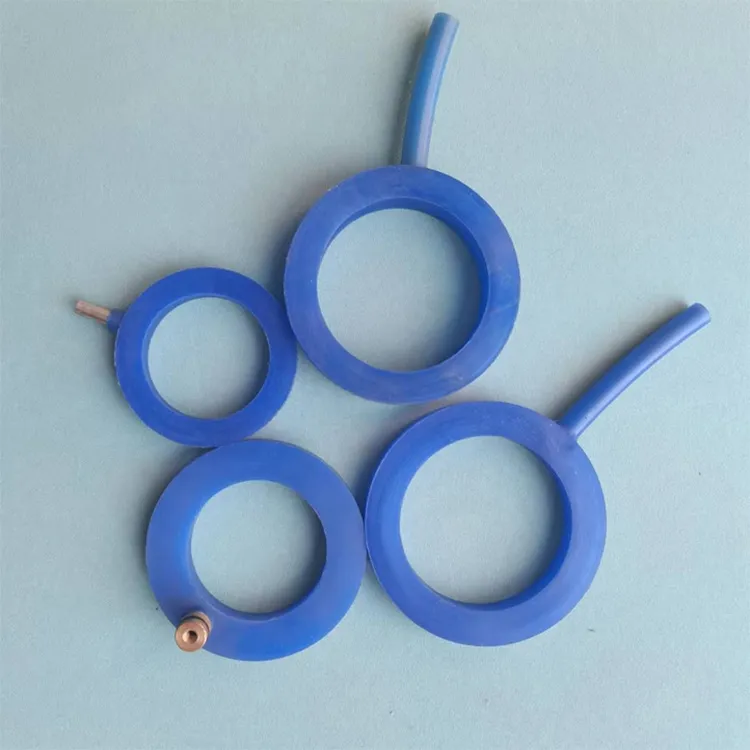

At SealShift, we understand that standard solutions don't always address unique sealing challenges. That's why we specialize in developing custom inflatable seal solutions tailored to your exact specifications and performance requirements.

Our expert engineering team works closely with you to analyze your application needs, environmental conditions, and operational parameters to design inflatable seals that deliver optimal performance even in the most demanding industry situations.

Whether you need specialized geometries, custom materials, unique mounting solutions, or integration with existing systems, our comprehensive design and manufacturing capabilities ensure we can create the perfect inflatable seal solution for your application. View our case studies to see examples of our custom solutions.

Specialized Sealing Solutions

Our custom inflatable seal capabilities address a wide range of specialized requirements across diverse industries and applications. Our product range can be fully customized to meet your specific needs.

Complex Geometries

Custom-designed inflatable seals for applications with irregular shapes, tight corners, or intricate contours that standard profiles can't effectively seal.

See our Super Yacht case study for an example of a complex geometry solution.

Extreme Environments

Specialized materials and designs for applications involving extreme temperatures, aggressive chemicals, radiation, or other challenging environmental conditions.

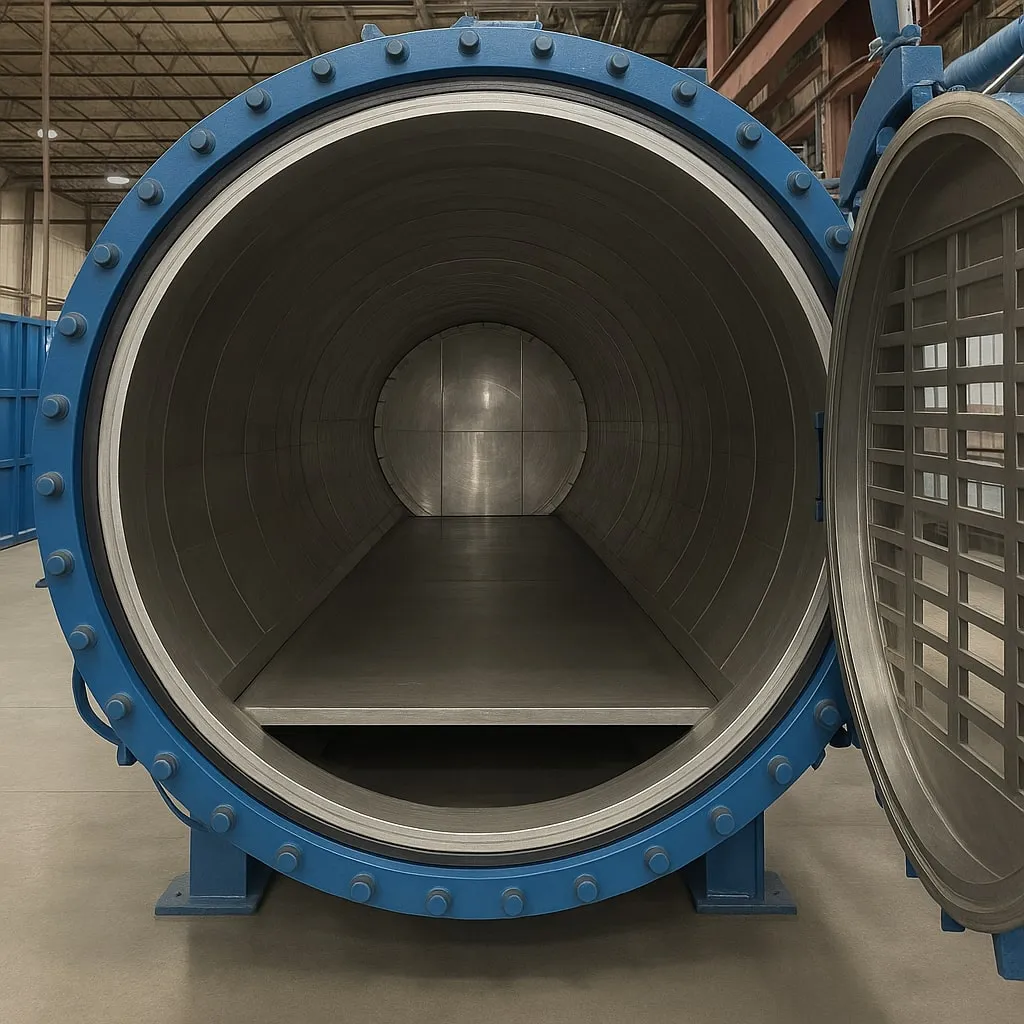

Read our Industrial Autoclave case study to see how we solved extreme temperature challenges.

CIP Applications

Specialized inflatable seals designed for Clean-in-Place systems in food, beverage, and pharmaceutical processing, allowing for effective cleaning without disassembly.

See our Pharmaceutical Clean Room case study for CIP-compatible sealing solutions.

High-Pressure Sealing

Reinforced inflatable seals designed specifically for applications requiring reliable sealing under significant pressure differentials. Ideal for autoclave applications and pressure vessels.

Large Diameter Solutions

Specialized manufacturing techniques for producing large-diameter inflatable seals with consistent performance across the entire sealing perimeter. Perfect for industrial door applications and large enclosures.

Space-Constrained Applications

Low-profile and miniature inflatable seal solutions for applications with limited installation space while maintaining effective sealing performance. Ideal for pharmaceutical equipment and precision instruments.

Our Custom Design Process

We follow a structured, collaborative approach to develop custom inflatable seal solutions that precisely match your requirements. Learn more about our design process and capabilities.

Requirements Analysis

We begin by thoroughly understanding your application, operating conditions, performance requirements, and constraints to establish a clear design foundation.

Design & Engineering

Our engineering team develops custom seal designs, selecting appropriate materials and configurations optimized for your specific application needs.

Prototype & Testing

We create prototypes for evaluation and perform comprehensive testing to verify performance under simulated operating conditions.

Production & Integration

After design approval, we manufacture your custom inflatable seals with precision quality control and provide support for integration into your application.

Industries We Serve

Our custom inflatable seal solutions address specialized requirements across a diverse range of industries.

Aerospace

Lightweight, high-performance seals for aircraft doors, hatches, and environmental control systems.

Pharmaceutical

FDA-compliant seals for cleanroom doors, isolators, and process equipment with validation documentation.

Semiconductor

Ultra-clean seals for wafer processing equipment, vacuum chambers, and cleanroom applications.

Food Processing

Hygienic, washdown-rated seals for processing equipment, doors, and access panels.

Nuclear

Radiation-resistant seals for containment doors, gloveboxes, and waste handling systems.

Marine

Corrosion-resistant seals for hatches, doors, and equipment in harsh maritime environments.

View our Superyachts industry page and the Super Yacht Hatch case study

Defense

High-performance seals for military vehicles, shelters, and equipment with MIL-SPEC compliance.

Wind Energy

Weather-resistant seals for nacelle doors, access panels, and maintenance hatches.

Featured Case Studies

Discover how our custom inflatable seal solutions have been implemented in real-world applications.

Ready to Solve Your Sealing Challenge?

Contact our engineering team today to discuss your unique requirements and discover how our custom inflatable seal solutions can enhance your application performance.